Automotive

Fail-safe and fully automatic production

Automation components for automotive production have special requirements for reliability and robustness. The most important process media here are compressed air and coolants, which have to be supplied without fail to welding, assembly and painting robots.

Only high-quality metal connection components are used for this demanding application. The Eisele BASICLINE offers the largest available assortment of screw-in fittings, push-in fittings, quick-release couplings, functional threaded joints and accessories for compressed air supply.

The LIQUIDLINE is available for the distribution of coolant. LIQUIDLINE components are available in dezincification-resistant brass as well as aluminum and stainless steel. The dezincification resistant material provides excellent protection against corrosion with most water types and applications. That makes these connectors the first choice for coolant distribution in welding applications in the automotive industry.

Products of the MULTILINE are used for connection of multiple media lines by means of a single multiple connector.

For painting robots we can recommend Series 1600 from Eisele’s INOXLINE. Made of stainless steel 1.4301/07, it was specially adapted for use with paints and has been proven over ten years of practical application.

Tubes and push-in connectors for systems in the automotive industry

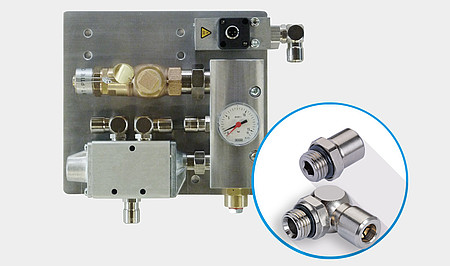

Klaus Günther GmbH manufactures primarily pneumatic components, assemblies and devices for the automotive industry. A special strength of the company, which is located in Sinsheim near Heidelberg, is the construction of coolant supply units and pneumatic logic controllers. Eisele supplies highly robust connectors and tubes for the systems, which are exceptionally leak-proof and corrosion-resistant.

The challenge

For a custom pneumatic circuit, Günther was in search of suitable connectors for the clean and effective design of the transitions and connections. The filtering system of a coolant supply system for welding robots also relies on connection technology that is “made in Germany,” since the high-quality and extremely robust Eisele connectors best fulfil these stringent requirements.

The solution

Günther GmbH used push-in fittings of the Eisele BASICLINE for the connection of the tubes in the company’s pneumatic circuit. In addition to their excellent leak-proof properties, the push-in connectors of this product line can also easily be disconnected and reconnected without leaking, even after extended use. This is an essential requirement in the closely synchronised assembly processes of the automotive industry. In addition, the very robust ProWeld tubes of high-quality polyether-polyurethane from Eisele are installed in the pneumatic circuit.

The filtering system of the coolant supply system for welding robots is equipped with a reduction from 1/2 to 1/8-inch, as well as several double nipples and a screw plug from Eisele. The cooling water installation itself includes four push-in connectors with a release ring (straight and angled), a tube nozzle with a union nut, various double nipples and ProWeld tubes with 3/8 and 1/4-inch diameters.

THE PRODUCT

The special technology of the push-in connectors of the Eisele BASICLINE enables the fast and easy assembly/disassembly of compressed air tubes. The standard versions of the BASICLINE connectors are manufactured from nickel-plated brass. They are suitable for use with tubes made of PE; PA, PU, PUR and PTFE.

- Available in numerous version and with diverse technical details

- Suitable for virtually all types of connections

- High leak prevention / application reliability

THE LIQUIDLINE PRODUCT

The cooling water supply system for the welding robots uses connections from the Eisele LIQUIDLINE of dezincification-resistant brass. This alloy was specially developed for closed cooling circuits requiring high corrosion protection. Depending on the particular application, LIQUIDLINE connections can also be made of stainless steel or aluminum. The highly robust and high-quality ProWeld tubes from Eisele are flame-retardant (UL 94 V0 to V2), externally calibrated and drag-chain compatible. They are equally suitable for use with compressed air and cooling water and have a Shore hardness of 52 or 58 D, depending on the size.