Regulations such as VDMA 8751:2019-03 for the specification and measurement of energy consumption for filling and packaging machines but also the competitors, set a higher focus on energy efficiency for machines and plants. Pneumatics is still widespread and offers high flexibility in the design of machines. However, leaks in the pneumatic circuit pose a high risk of unnoticed losses. The efficiency of the machine decreases, more electrical energy has to be used and as a result CO2 emissions increase. For these applications, Eisele has the INOXLINE push-in fittings series 17A and 17B in its standard product range. Due to their design and advanced sealing technology, they provide long-term and reliable tightness and achieve a particularly long service life thanks to their high-quality workmanship. In addition, a high surface quality and a full nominal width guarantee a smooth and efficient media flow.

| Series 17A | Series 17B |

| Increased safety | Increased mounting safety |

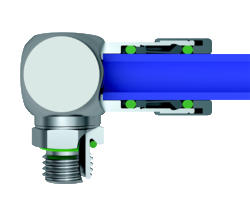

The special sealing technology of the 17A series with two FKM seals can withstand both internal gas pressures of up to 24 bar and a vacuum pressure as low as -0.95 bar. The second seal in the connections not only enables use under higher pressures, but also offers additional safety to prevent dirt from penetrating the system. THE PROPERTIES AT A GLANCE:

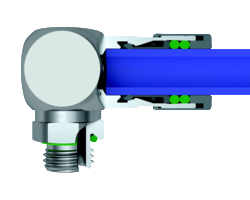

| With the advanced development of the 17B series, Eisele has furt her optimized the sealing system of the successful INOXLINE push-in fittings. In the new design, the O-rings are installed in front of the collet which fi x the tube in place. Due to that concept it is possible to avoid mounting errors that can lead to micro scratches on the tubes surface. THE PROPERTIES AT A GLANCE:

|